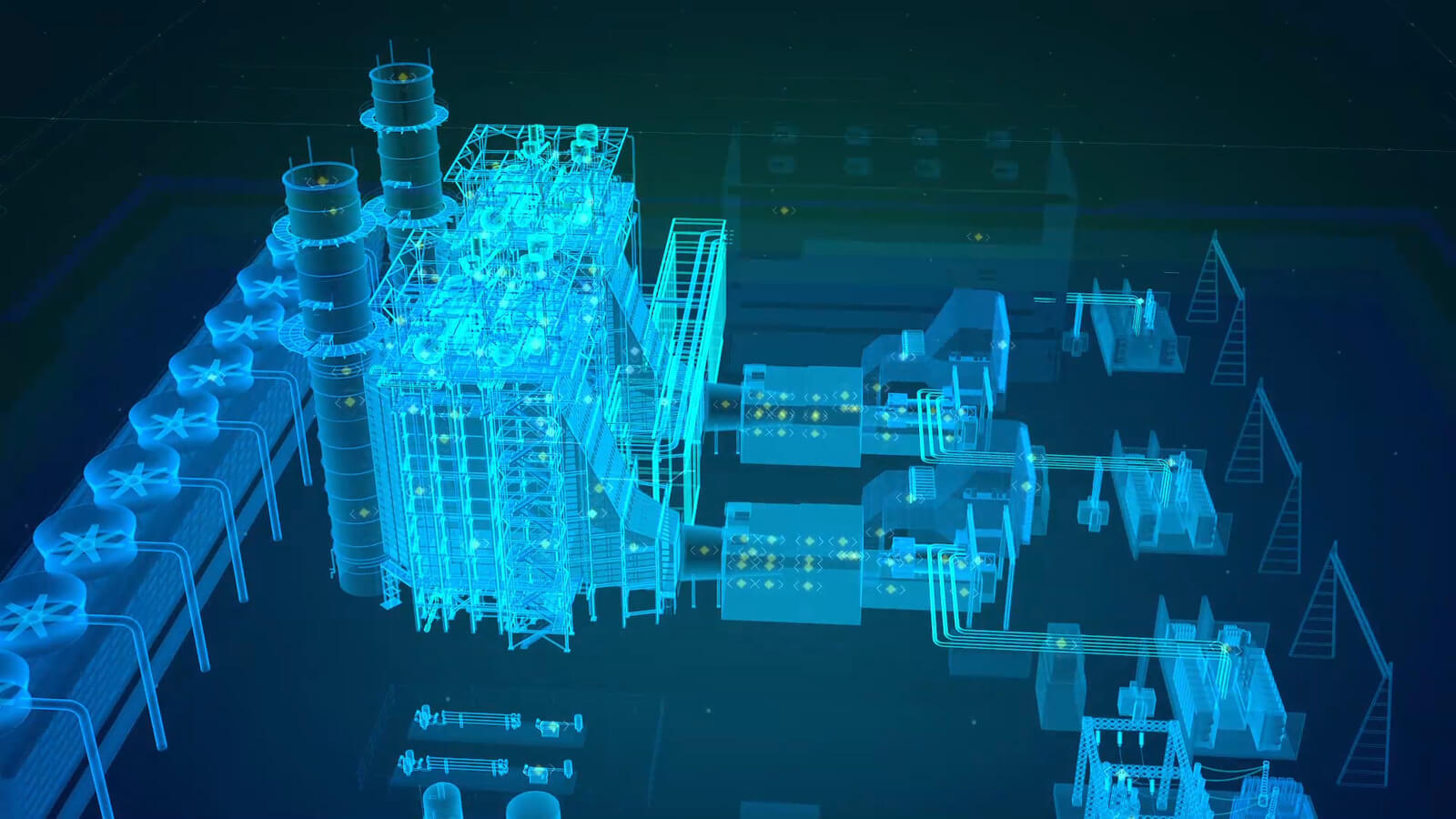

Today we lift the veil on the educational process of the students studying at Petroleum engineering faculty. They prototype processes in the downholes using digital production fields.

These technology allows to make the stages of the oil production and obtain correct data in real time operation automatically controlled, in order to ensure the most efficient and stable well operation.

BP (Field of the Future), Shell (Smart Fields), Total (Field Monitoring), Chevron (iField) have been using this technology already!

During educational process, students use automation technologies. In particular, programs based on Visual Basic for Application and Python. They use OIS +, BaseGIS and Wellinfo to collect and store data. The LoraWAN + system allows to determine the virtual volume of the fluid in the well.

Using the software package "Engineering evaluation of well construction" by LLC "Bursooftproject" and software of the Landmark company future engineers perform well drilling process design and its control process. For the most effective learning, students use remote control and visualization tools, such as volumetric objects and 3D glasses.